Behavior of chemical

Human health effects of hazardous chemicals

Response exposure limits

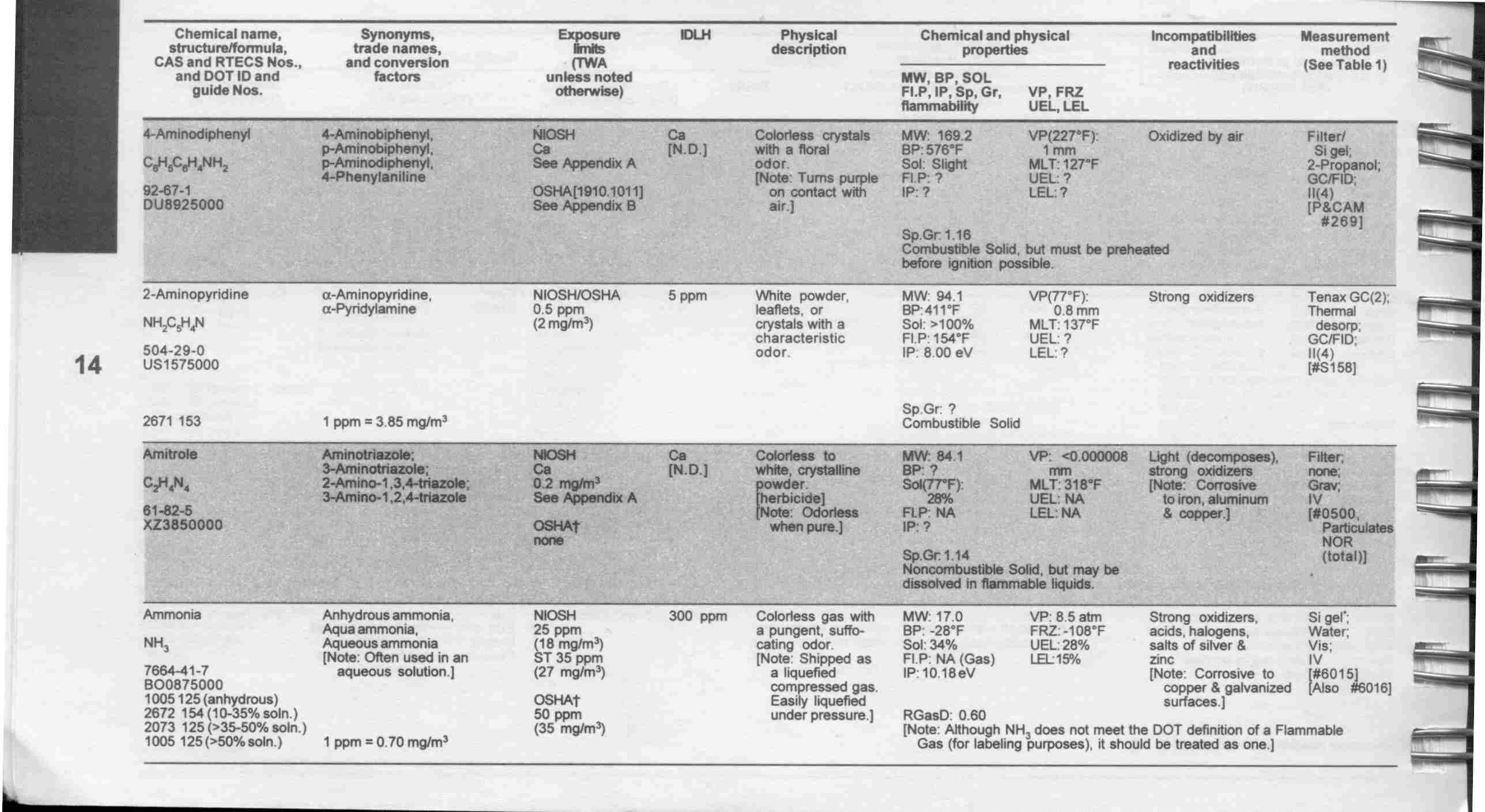

NIOSH pocketguide

Level A

Level B

Level C

Level D

Chemical protective cloths

Site control

EPA suggested Decontamination line

Hazard identification

There are many terms that used to identify chemicals. Most chemicals were classified by the method of listing of federal agencies; OSHA, EPA, DOT.

OSHA defined the chemicals as hazardous chemicals that might

have potential hazards to human health. The terms of classification are on

purpose to protect human health. The regulation enforced producer or manufacture

to comply with safe environment of employees and people in community. In 29 CFR

1910.1200 Hazardcom, requires manufacturer to prepare Materials Safety Data

Sheet (MSDS) to provide information

about the hazards of the chemicals in operating or handling activity.

EPA defined chemicals in the term of hazardous chemicals

that can present danger to the environment. The report must be send to EPA in

case of chemicals spill exceeding the report quantity on the purpose to protect

air, ground and water resources. EPA also regulated the Hazardous waste

under the Resource Conservation and Recovery ct 1976 RCRA to institute

waste management program initiating “cradle to grave” for tracking of

hazardous waste.

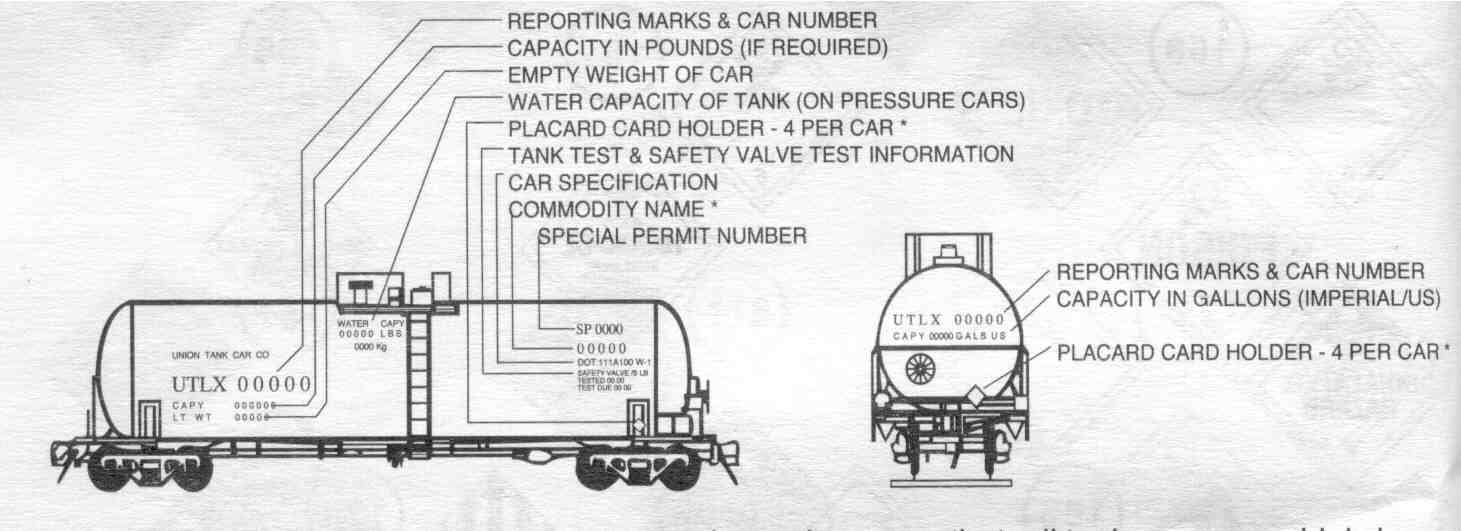

DOT defined term of hazardous materials (dangerous goods)

that may present danger during transportation by truck, rail, air, or water. In

49 CFR, DOT was established criteria for packaging, labeling, placarding,

shipping paper, and the training and responsibilities of transportation

personnel.

Hazard terminology labeling and placard

IMO

classes and division Vs. DOT

Class 1 Explosive

1.1

mass

explosive

1.2

projection

hazard

1.3

fire

hazard

1.4

no

significant hazard

1.5

very

sensitive substance

Explosive A ; function by detonation

Explosive B ; function by rapid combustion

Explosive C ; manufactured articles containing

Class 2 Gases

2.1 flammable gases

2.2 non-flammable gases

2.3 poison gases

DOT same

Class 3 Flammable liquids

3.1 low flash point < 0 F

3.2 intermediate flash point (0 –37 F)

3.3 high flash point (73- 141 F)

DOT Flammable liquid (flash point <100 F)

Combustible liquid (flash point 100- 200 F)

Class 4 Flammable solid or substances

4.1 flammable solids

4.2 substances liable to spontaneous combustible

4.3 substances which emit flammable gas when wet

DOT Flammable solid

Flammable solid/liquid (pyroforic)

Flammable solid with dangerous when wet label

Class 5 Oxidizing substances

5.1 oxidizing substances

5.2 organic peroxides

DOT same

Class 6 Poisonous or infectious substances

6.1 poisonous substances

6.2 infectious substances

DOT poison B

Etiologic Agent

Class 7 Radiological materials

DOT same

Class 8 Corrosives

DOT same

Class 9 Miscellaneous danger substances

DOT ORM (other regulated materials)

: four sections and different colors on placard are used to classify

potential hazrads. Number (0-4) indicate the severity of hazards.

RED (top); Flammability

4 very flammable gases

3 can be ignited at all normal temp

2 need moderate heat before ignite

1 must be preheated before ignition

0 not burn

BLUE (left); Health

hazard

4 too dangerous need SCBA and CPC

3 extremely dangerous need SCBA no skin contact

2 materials hazardous to health still need SCBA

1slightly hazardous to health may need SCBA

0 expose under fire condition like ordinary combustion

YELLOW (right); Stability or Reactivity

4 explosive at normal temp.

3 explosive but require strong ignition source

2 unstable material rapid release energy and heat but not detonate

1 normal stable but can be excited by temp.

0 stable even under fire

WHITE (bottom); other information

EX, “Oxidizers”

ID

Number has four digits to identify chemical and

emergency responses in DOT guidebook

EX, ID 1831 = sulfuric acid, 1005 = ammonia anhydrous

Chemical Trailer

Placard and sign on rail car

Boling

point (BP)

is the temperature at which a liquid began to change to be vapor phase. If the

boiling point is lower than the air temperature around chemical, the chemicals

will boil and become vapor. In some chemicals, ex, Hydrogen chloride (HCl) bp =

-85 C, the chemical is present in gas form at ambient temperature. The leak of

chemical will be seen by the form of toxic fume (slightly yellow gas) and may be

carried by wind.

Vapor

pressure represents

the pressure inside of a closed container by the vapor in the space above the

liquid the container hold. The pressure unit is determined by the mm Hg that

vapor can push. The high vapor pressure chemicals are more likely to breach

their container when heated. Chemicals with high VP are more volatile and more

vapor will present at spill area. Ex, at 75 F, water = 21 mmHg, Ethyl alcohol=

44 mmHg, Chlorine= 4,800 mmHg

Vapor

density is

the mass of vapor divided by the volume filled. VD grater than 1.0 will sink on

the floor. If the leak is a heavy vapor and inflammable, the leak will travel

along the ground to ignition sources. Ex, gasoline VD = 3-4.0 or toluene VD=

2.49

Solubility

and specific gravity are

indicated the status of chemical in the water. Lower solubility can be

easily to separate from the water in the from of the layer or separated part in

water. The specific gravity is referred by comparing of the water at 1.0. The

high specific gravity will sink and the lower specific gravity will float on the

surface of water. For high solubility the chemicals will dissolve in the water

by varying of temperature. The spill control might be very difficult when high

solubility spills are present in the water.

Flash

point is a

minimum liquid temperature at which the vapor will be present above liquid to

ignite. The lower flash point is higher fire hazard. All ignite sources must be

removed from the area near the low flash point chemicals. Ex, gasoline = -45 F,

Ethyl alcohol= 55 F

Explosive

limit range is

reresent the concentration of material that permit the material to burn. LEL

(lower explosive limit) is the lowest ignitable concentration and ULE (upper

explosive limit) is the highest ignitable concentration. The percent or

concentration greater than UEL or lower than LEL will present the range of

non-explosive concentration. Ex, LEL of acetylene gas =3 % and UEL =82%. The

explosive range is 3-82%.

Water-reactivity

materials react

with water to release heat or flammable toxic. If there is a fire in which water

is used as extinguisher, the presence of water can make more danger. Ex,

sulfuric acid leak can generate more heat or potassium and sodium can react with

water producing hydrogen gas.

Oxidizers

The

oxidizers that contain oxygen may release that oxygen as decomposed helping to

sustain a fire. Ex, organic peroxides, acetyl peroxide, peracetic acid, are

considered very dangerous hazards, and also inorganic peroxides like sodium and

potassium peroxide.

Unstable

materials

are those that have a tendency to decompose by themselves. They generate heat or

gas even burnt to a flame or explodes. Some monomer plastics can spontaneously

form polymer causing rupture and explode of container. Ex, PVC monomer, resin,

synthetic rubber, and also include organic peroxides too.

Incompatible

materials

the reaction of some materials can cause heat, violent reaction and toxic fumes.

Ex, (spent caustic + spent acid) =

heat, (asbestos + cleaning solution) = toxic substance, (water + sodium) =

flammable gas

Radioactivity

Radioisotope

chemical can give of energy to knock off electron in molecule or tissue causing

adverse effect. Ex, radon gas, uranium 235, strontium

Mutagens

are the

chemicals that can damage human DNA or any genetic materials in human cells.

Although automatic repair can be occurred by human cells, the results of the may

present changes in DNA or and functions of cells. The changes may lead cancer

cells or some variety of illnesses in human. Ex, Hydroxylamine, Radon gas, or

high intensity of UV

Teratogens

are the chemicals that cause damage in the unborn baby.

Lead is known as a teratogen causing brain damage in offspring.

Neurotoxins

are the

chemicals that can damage brain or sensory or motor nerve communications. Some

organic solvents, for ex, toluene or methyl ethyl ketone, can cause damage in

central nerve system.

Hepatotoxins

are the

chemicals like Hydrogen cyanide, formic acid, or many chlorinated solvents that

can damage liver tissue.

Nephrotoxins

Some workers in assembly plant and metal work can

have more double in the risk of kidneys disease. The damage will not be found

until ¾ of the functions are failed. Arsenic and lead are the examples of

nephrotxins.

Blood

circulation toxins

Ex, CO can form HbCO that is nearly 210 times affinity that oxygen or cytotoxic

hypoxia which blood cells lose ability to utilize the oxygen by the chemicals,

ex, hydrogen sulfide or hydrogen cyanide

The National Research Council’s Committee on Toxicology has published the exposure limits for emergency responders and general public. Emergency Exposure Guidance Limits (EEGLs) and Short-term Public Emergency Guidance Levels (SPEGLs) were published for the protection of people in the community. EEGls are set for protecting the occupational groups such as firefighter, Hazamat responders that typically is younger and healthier than the general public. SPEGLs are set to protect public from effects that might be irreversible or incapacitating. For protecting general population, the Federal Emergency Management Agency (FEMA) lists the following options in order to decrease preferences:

Consult a toxicologist

Use high values among these following:

IDLH/10

TLV-STEL

TLV-TWA

TLV-C

(**for only less than 1 hr operation with no carcinogen**)

Personal Protective Equipment

Chemical

protective clothes and gloves

Chemicals protective clothes are required to protect skin from the chemicals that can absorb and pass through others organ of human body. The selection of CPC has to consider the concentration of chemicals and breakthrough time that protective suit can stay protecting the users during performing the activities. The attack of chemicals to CPC can be classified as permeation, penetration, and degradation. Permeation refers to the process that solid, liquid, or vapor can passes through protective material at molecular level. Penetration refers to bulk movement of chemicals pass through the pore, small flaws, or imperfect seam such as zippers, pinholes or any crack on suit. Degradation refers to the loss of physical resistance to chemical due to chemical reaction. Moreover, the physical wear or abrasion can cause damage to protective suit. The operator has to consider the body heat that generate during the activity and also the radiant heat from some heat sources in operating area in case of fire of work near heat source.

Gloves

and boots are the most protective equipment that contains a lot of contaminants

from the spilled area. Gloves and boots are used to protect arm from both

chemical and physical hazards. Sometimes, selected gloves must cover in both

physical and chemicals two-layers or outer gloves may need for high protection.

·

Site control

Controlled

zones in spilled area

Hot Zone

This location is the area where chemicals hazard was released. This area is the most

dangerous in the site. The hot line is determined based on the risk and hazard

assessment. The PPE are required for operator in emergency response.

Warm Zone (contamination reduction zone)

The warm zone is the area between hot zone and cold zone (uncontaminated area). This area can serve as buffer zone from the spill. The PPE and support equipment for decontamination process are set up in this area. The protective gears are refilled or changed and clean up processes for operator are done in this area.

Cold Zone

The

incident commander post is set up in this area. PPE is not required for the area.

This area provide communication and first aid and medical procedures

·

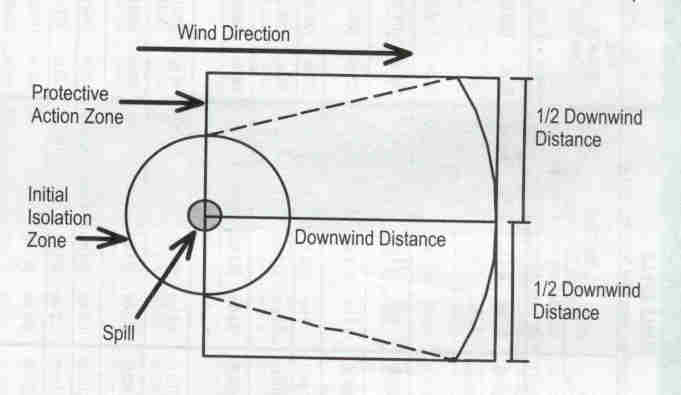

Confining operation

Confining processes are considered as defensive operations. The selection of appropriate procedures in release control can reduce the spread of chemicals through the public area and reduce among of cost in clean up process. The types of release can be classified in the ways the contaminants can migrate or spread out to the public area. The effective control requires the prediction of the pathways that hazard chemicals will migrate and the factors that support the release, ex, wind, rain, flow direction of current, or shape of earth’ surface.

Land release and control

Diking

involves construction

to confine the migration of spilled hazardous chemicals. Constructing dams by

soil or chemical barrier are required may be in series to stop the release.

Diversion

refers to

the constructions that change or control the pathway of chemicals to protect the

public areas or try to collect the hazardous chemical in the specific place for

cleanup.

Inlet

blockage

requires tight seals at entry point

Water release and control

Heavy insoluble materials

o

Overflow dam

o

Catch basin

Light insoluble materials

o

Barrier or sorbent booms

o

Underflow dam

o

Filter fences

Soluble materials

o

Seal booms

o

Dam

o

Chemical treatment

Air releases and controls

Vapor knockdown by using direct fog

patterns from fire hoses through the chemicals cloud. This method is most

effective in water-soluble materials

Vapor suppression by

using foam blanket to cover toxic vapor. Generally, aqueous film-forming foam

(AFFF) is used to cover on the flammable liquid spills. However, if the

flammable liquid is polar solvent the may be dissolved, reducing foam

effectives.

Containing

processes are considered as offensive operations. The operations are performed

at the source of release. The operators are required extremely protective level

due to the highest hazard potential in this area. Response personnel should not

try to perform containment operation at the point of release before the

procedures and the protective gears have been explored.

Assessment

consideration for selection of containment

In order to identify the procedural option the specific factors related

to the release must be classified. The factors generally can be listed as

follows:

Properties of hazard materials

Physical state; solid, liquid, gas

Physical properties; vapor pressure, density, solubility

Toxicity and flammability; flash point

Reactivity

Characteristic of container

Size and amount containing

Materials the container made of

Characteristic of breach

Size of opening

Shape of opening

Location

Volume and rate of release

Expect duration of release Equipment

required

Wooden plug, Expandable pipe plug, boiler plug, metal screw with gasket,

toggle bolt patches

Adhesives epoxy, plug and patch putty

Sealant and gasket; viton sheet, neoprene sheet, duct tap

Clamp, strap and gasket holder

Valves and fittings Plugging Patching Pump and

vacuum collection Sorbent collection by using sorbent contained in sheet, rolls, or boom Solidification

by solidifier Gelation by using gel-forming chemicals Decontamination line for level A and B Exercise Emergency Plan Levels of exercise Typically,

is used as the introduction for individuals who are in the part of emergency

response. It provides instruction and explanation of overall plan. Tabletop

is the process of sharing the information of each individual. The practice

problems are set for the exercise in decision-making process. It brings people

to form a group in order to exchange the information and provide the best

alternative solution. It is response procedure

to demonstrate the understanding of response plan. The real equipment and PPE

are used like ordinary task. The simulation of emergency action may be performed

to evaluate the effectiveness of emergency plan. Sometime, it is called “hand

–on” activities It offers opportunity for

full implement ERP for specific scenarios. This exercise enhances realism. All

equipment and activities are simulated as the real emergency situation.

The exercise processes